Introduction to Sewage Treatment Plant

Sewage treatment refers to the process of removing contaminants, microorganisms, and waste products from wastewater, primarily from residential, commercial, and industrial sources. Raw sewage typically originates from toilets, sinks, showers, kitchens, and laundry. The treatment process involves physical, chemical, and biological methods to ensure that the wastewater is treated to meet environmental standards before being released or reused.

- Technologies We Offer:

- Activated Sludge Process (ASP)

- Sequential Batch Reactor (SBR)

- Membrane Bio Reactor (MBR)

- Submerged Aerobic Fixed Film Reactor (SAFFR)

- Types of STP:

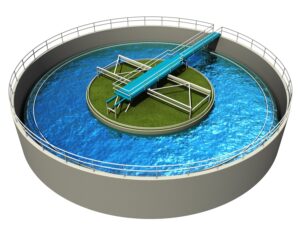

- Prefabricated STP

- Containerized STP

- Civil STP

Product Description

- Our Sewage Treatment Plants (STP) use innovative technologies to clean wastewater, making it safe for reuse and for environmental discharge. These plants follow a structured three-stage process to remove harmful sediments, bacteria, and nutrients:

- Primary Treatment: Removes large particles and grease.

- Secondary (Biological) Treatment: Organic matter is broken down by microorganisms.

- Tertiary Treatment: Further purification, including filtration and disinfection, to ensure safe treated water.

- The treated water meets all environmental discharge standards and can be reused for industrial, irrigation, or other non-potable purposes. Our systems are designed to be efficient, cost-effective, and easy to maintain.

Functionality

- The treatment begins with primary treatment where solids are separated from the wastewater, followed by secondary treatment, which uses biological processes to further break down organic contaminants. The final step is tertiary treatment, which involves additional filtration and disinfection to remove any remaining harmful substances.

- The plant can be designed with various configurations based on the type and volume of wastewater, ensuring optimal performance. Our systems are available in both automatic and manual modes, depending on your requirements.

Feature

- Eco-friendly: Promotes recycling and reduces water consumption.

- User-friendly: Easy to operate and maintain.

- Compact & Efficient: Space-saving design without compromising on performance.

- High-Quality Treated Water: Meets regulatory standards for environmental discharge.

- Cost-Effective: Low operational and maintenance costs.

- Scalable: Suitable for a variety of wastewater generation sources.

Advantages

- Residential: Household wastewater treatment.

- Commercial: Wastewater treatment for hotels, restaurants, and businesses.

- Municipal: Community-scale treatment for cities and towns.

- Industrial: Tailored solutions for industries such as food, textile, pharmaceuticals, etc.

PLANTS WE OFFER

Frequently Asked Question

The primary purpose of an STP is to remove contaminants from wastewater, making it safe for the environment or for reuse. This prevents pollution and protects water bodies from harmful chemicals and pathogens.

STPs use a combination of physical, chemical, and biological methods to treat wastewater. The wastewater passes through various stages, including screening, sedimentation, biological treatment, and disinfection, to remove impurities.

Common technologies include:

- Activated Sludge Process (ASP): Uses aeration tanks and microorganisms to treat wastewater.

- Membrane Bio Reactor (MBR): Combines membrane filtration with biological treatment.

- Sequential Batch Reactor (SBR): A time-based treatment system.

- Submerged Aerobic Fixed Film Reactor (SAFFR): Provides efficient biological treatment by using fixed-film aeration.

The by-products include treated water, which can be used for irrigation or industrial processes, sludge that can be repurposed as fertilizer, and biogas, which can be used as an energy source.

- Reduces water pollution and improves water quality.

- Helps in the recovery of water resources, energy, and nutrients.

- Minimizes odors and environmental impact.

- Ensures compliance with regulatory standards.