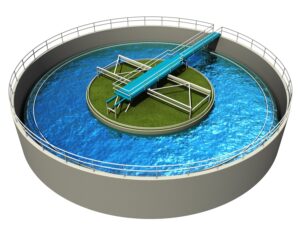

Introduction to CLARIFIER SYSTEM

Purewater Expert offers a comprehensive range of clarifier systems, including High Rate Solid Contact Clarifier (HRSCC), Tube Settler (TSU), Clariflocculator, and Lamella Settler. These systems are designed for efficient and continuous removal of settleable solids from water and wastewater, meeting diverse client requirements. Our systems are tailored to various specifications, ensuring seamless adaptability to specific applications.

Purewater Expert’s Clarifier System delivers unmatched efficiency in solid-liquid separation, combining robust design, low energy consumption, and exceptional water clarity to drive sustainable water solutions.

Product Description

The clarifier system plays a crucial role in reducing suspended solids, colloidal silica, and heavy metals from wastewater. Utilizing the principles of Coagulation/Flocculation and Hydraulic Separation, our clarifiers efficiently separate solids and produce clarified water. During the coagulation/flocculation phase, feed water interacts with chemical mixtures and sludge particles to form larger flocs. These flocs settle in the clarification zone, leaving behind clean water.

The system includes robust internal components such as a draft tube, recirculator, flash mixer, gearboxes, and inlet/outlet launders, all integrated with a chemical dosing system to ensure consistent performance.

Functionality

Clarifiers work based on the principle of gravity sedimentation, separating suspended solids and solid particulates from liquids. These systems are essential for water and wastewater treatment, especially when dealing with higher concentrations of suspended solids. As solids settle to the bottom of the clarifier, they are removed as sludge or scum.

Clarified water is collected through overflow weirs, ensuring clean water output. The concentrated sludge is recycled as Return Activated Sludge (RAS) or disposed of as Waste Activated Sludge (WAS).

Feature

- In-house design and manufacturing

- Integrated flash mixer, flocculation, and thickener mechanism

- Capable of handling high inlet suspended solids (up to 3000 ppm)

- Produces treated water with low TSS (less than 10 ppm in raw water and less than 30 ppm in wastewater)

- High-efficiency turbine for optimized energy and chemical usage

- Proven modular designs with multiple installations

- Compact and easy-to-operate design

- Minimal chemical requirements with consistent water quality

- Adaptable to variations in inlet water parameters

Advantages

- Primary treatment in water and wastewater treatment

- Suspended solids removal

- Reduction of turbidity in water

- Elimination of colloidal silica

- Industrial and municipal wastewater treatment

PLANTS WE OFFER

Frequently Asked Question

A clarifier system separates solid particles from liquids, making it a critical component in water and wastewater treatment. It is used for clarification, thickening, and removal of suspended solids.

Clarifiers utilize gravity to settle solid particles at the bottom of a tank. The clarified water flows out from the top, while settled sludge is collected and either recycled or disposed of.

Clarifiers include High Rate Solid Contact Clarifiers, Tube Settlers, Clariflocculators, Lamella Settlers, circular clarifiers, rectangular clarifiers, and dissolved air flotation clarifiers.

Clarified water and sludge are the primary by-products. The clarified water is reused or discharged, while sludge undergoes further treatment or disposal.

Advantages include improved water quality, reduced sludge volume, lower operational costs, and optimized wastewater management.